In an industry often constrained by legacy processes and fragmented workflows, Legendre Group leads with its digitalization journey. The French construction group, headquartered in Rennes, with a 80-year history, a team of more than 2400 people and projects spanning from London, through Paris, to Lisbon, has placed digital transformation and open standards at the core of its strategy.

Legendre Group has an integrated Digital Construction Department. Since 2022, the department is led by Thomas CROUAN and is composed of 10 members with various expertises in modeling, 3D coordination and BIM management by monitoring digital models.

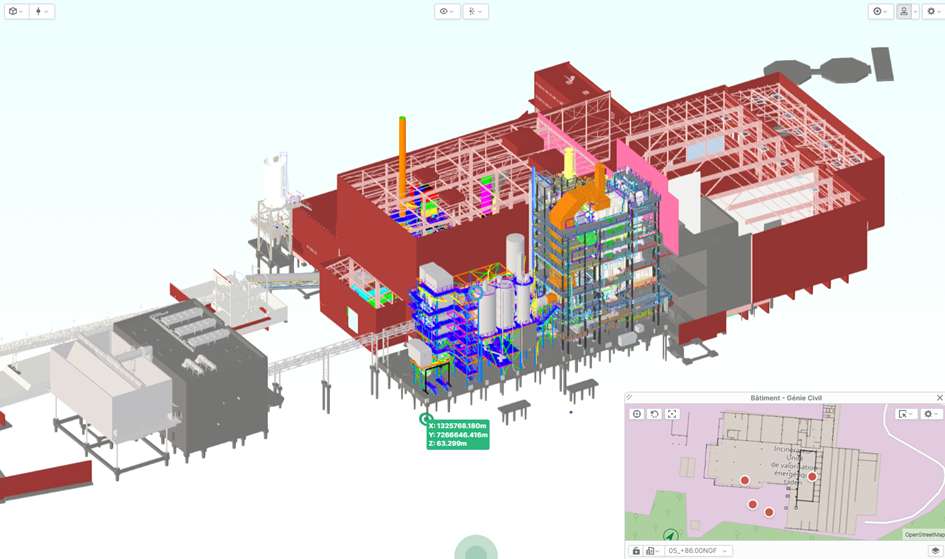

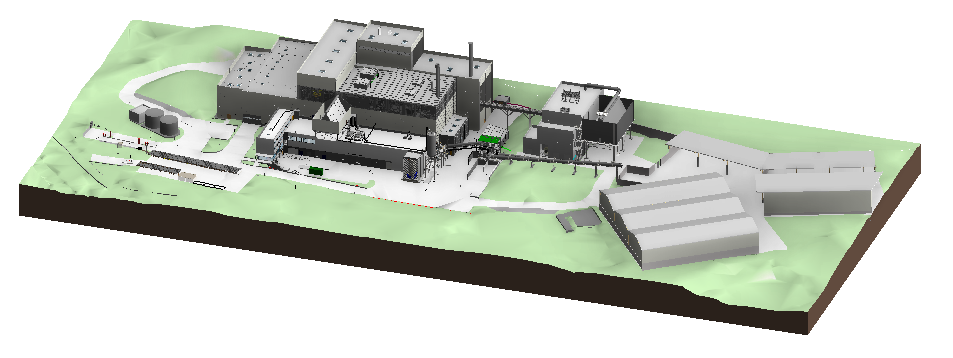

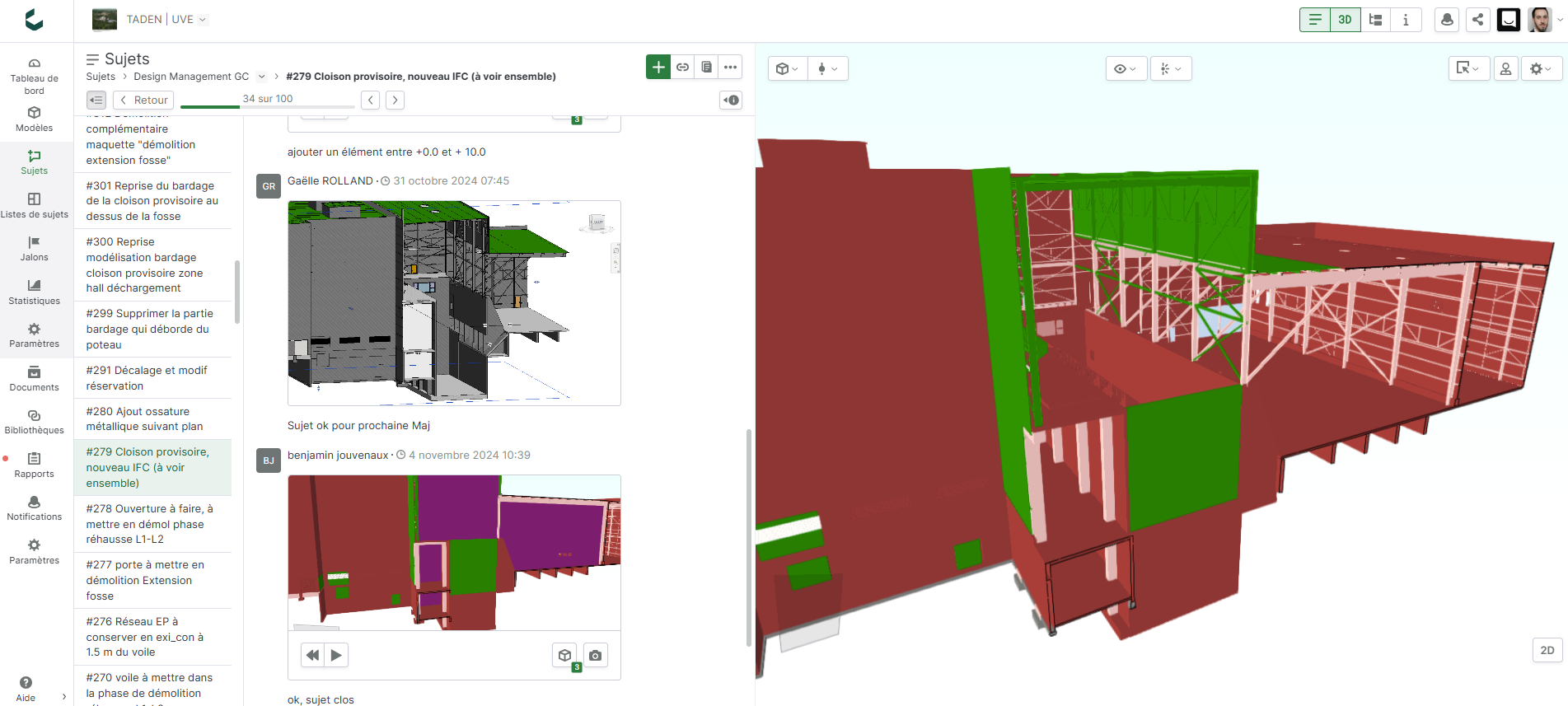

Legendre’s work on the Taden Energy Recovery Plant (UVE) stands as a prime example of this philosophy in action, demonstrating how a commitment to open BIM can unlock value and improve efficiency on even the most complex projects.

We recently spoke with Damien Lefranc, Team Leader of Digital Construction Services at Legendre, to understand his team’s mission and how they are leveraging technology to improve collaboration and project delivery.

The Challenge: Complexity as a Catalyst for Change

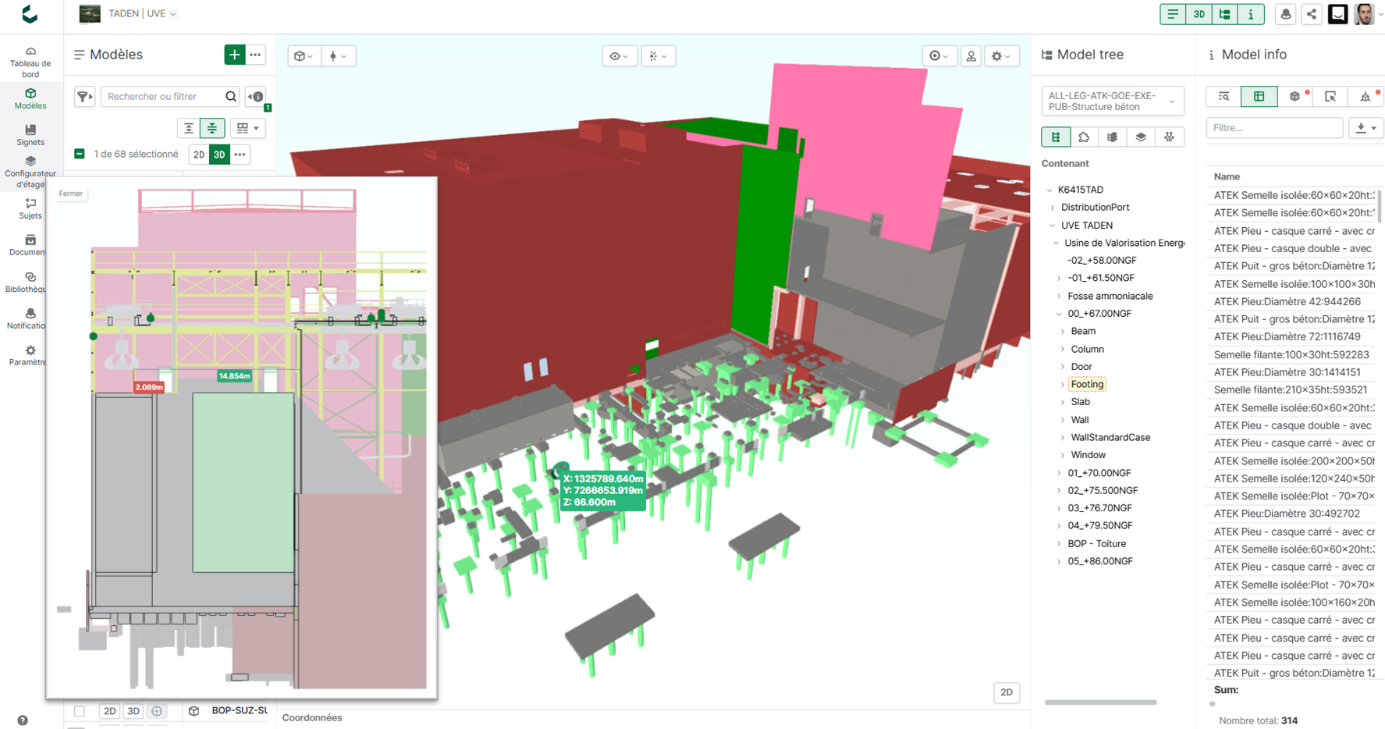

The Taden UVE project is far from a simple build. It is a large-scale, 132 million euro refurbishment of an existing facility, with the goal of increasing its capacity to convert domestic waste into 99 GWh of electricity per year. The project involves multiple phases and zones, with simultaneous design and construction work, and a diverse range of collaborators. The Legendre team worked closely with SUEZ, managing civil works while SUEZ handled the industrial side. Damien was assisted by Yasmine Hajji from SUEZ, who he credits with “doing a huge job of evolution of practices for the industrial part”.

For Damien, it is precisely this complexity that makes this, and other similar projects in Legendre’s portfolio, perfect use cases for advanced digital methods. “It’s the project and the current collaboration between stakeholders that drives the need for an open BIM approach,” he explains.

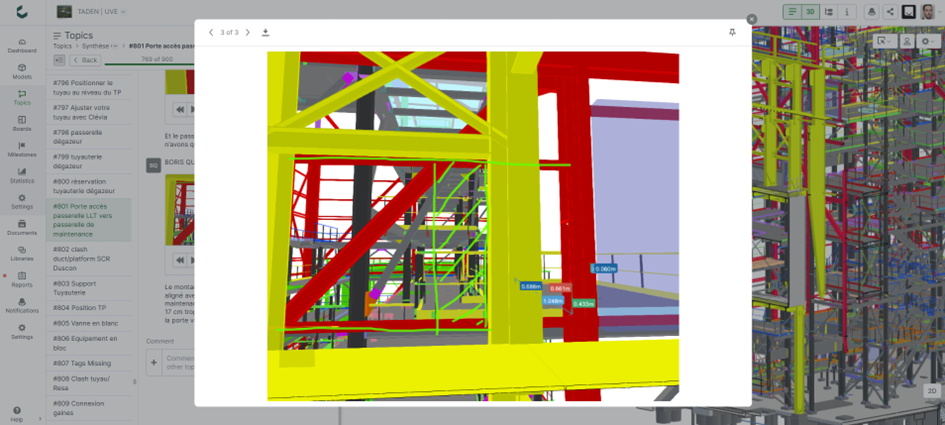

In a complex environment like Taden, which brings together different software (Bricscad, Solidworks, Revit, Bocad) and teams from various countries speaking different languages, interoperability is not a luxury – it is a necessity. This is where closed, proprietary systems fail. “Closed BIM is a very bad solution for this kind of project,” Damien asserts. “We would spend too much time and money converting models and making them accessible for all team members.”

Building an Ecosystem of Collaboration

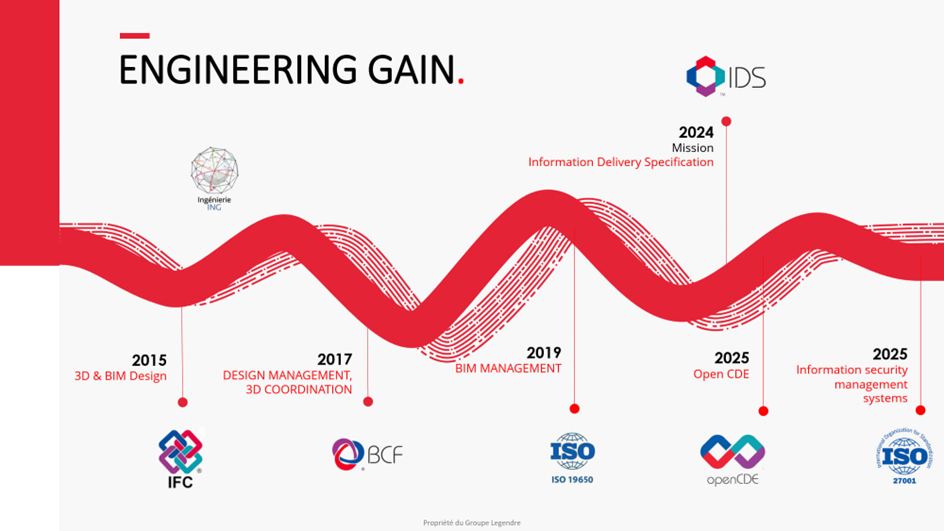

Legendre’s commitment to open BIM is not a new development. The company has been using open standards like IFC and BCF since 2015. This long-term dedication has enabled them to build a robust digital ecosystem that extends beyond their internal teams to include long-standing subcontractors and partners, from design to the construction site.

“For the more regular ones, they know where to go to get the information,” Damien says of their subcontractors. He recalls a time when some were hesitant to adopt BIM on-site. Today, he says, it’s a different story: “It’s not a subject anymore. We can even say that on projects, it’s the subcontractors who call us asking, ‘Have you put Catenda in place or not? Where can we find the information?'”

This shift is a testament to the Legendre team’s approach: to promote the use of digital models not by mandate, but by demonstrating their value. “It’s important not to force teams to use BIM,” Damien states. “The BIM approach must be easy to access and inexpensive.”

Catenda Hub, a Common Data Environment (CDE) built on open standards, serves as the central platform for this collaborative ecosystem. Its ease of use has been a key factor in its adoption. As Damien notes, the goal is to make digital models and tools accessible even to non-specialists on site, a crucial factor in a project with over 100 users.

Measuring Success Beyond the Bottom Line

While many companies focus on quantifying time and cost savings, Damien’s team has a more nuanced perspective. They are focused on quality and reducing on-site stress, factors that are difficult to measure but have a profound impact on project success. “Each project is a prototype,” Damien says. “What we can truly measure is the quality of the work…This is measured by less tension on site.”

He is quick to offer an example of this qualitative gain from the Taden project: “My greatest reward comes from feedback from the crew and the site manager, like hearing that using models made it easier to carry out the piling work via extraction of point coordinates.”

This focus on the end-user extends to the company’s broader digitalization strategy. A perfect example of this is the case of Nicolas, a site manager who was initially hesitant to adopt the BIM approach due to past experiences. He was convinced by Damien’s team, who set up Catenda in a way that directly addressed his team’s specific on-site needs. Today, Nicolas is a convert, asking his own teams to use the platform.

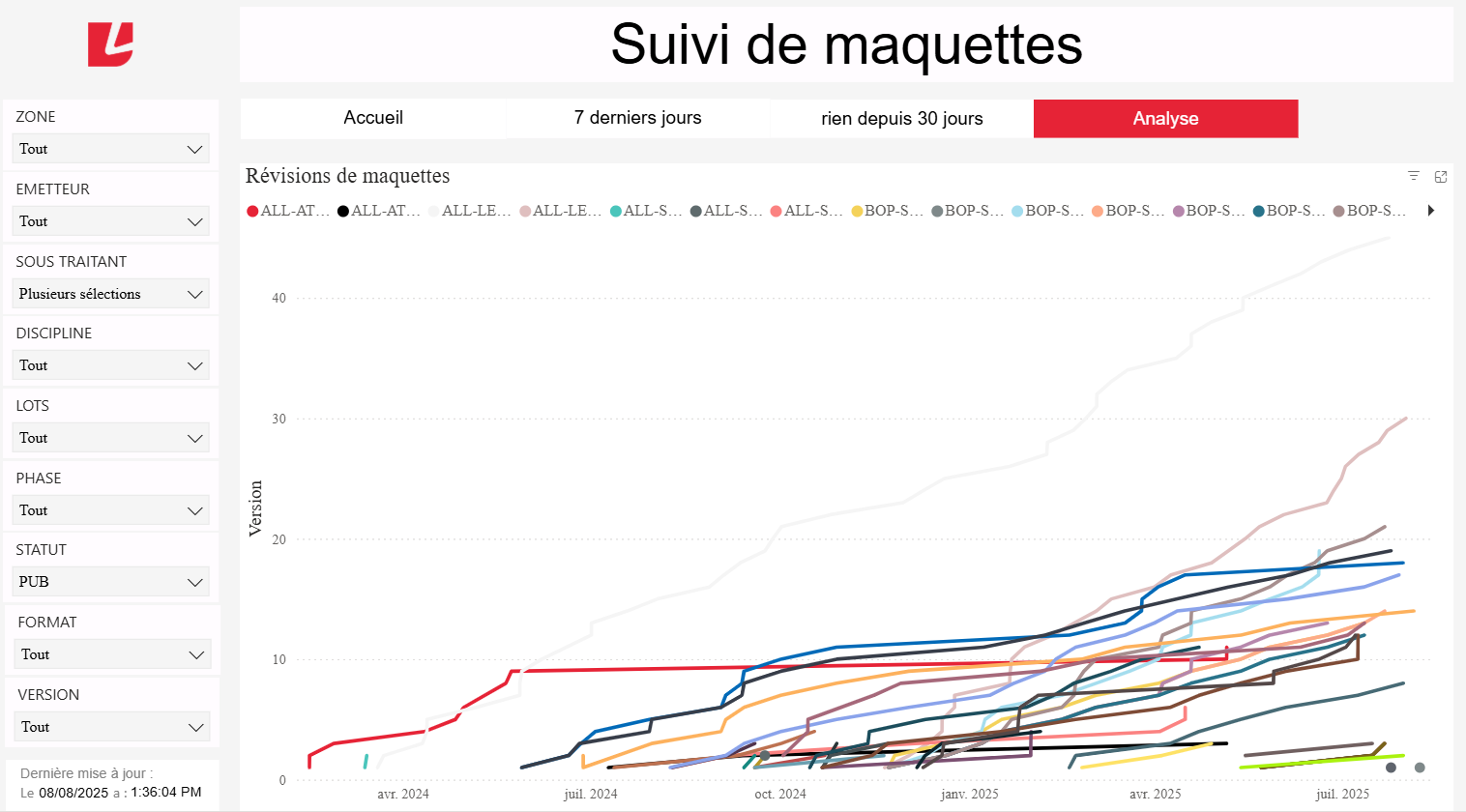

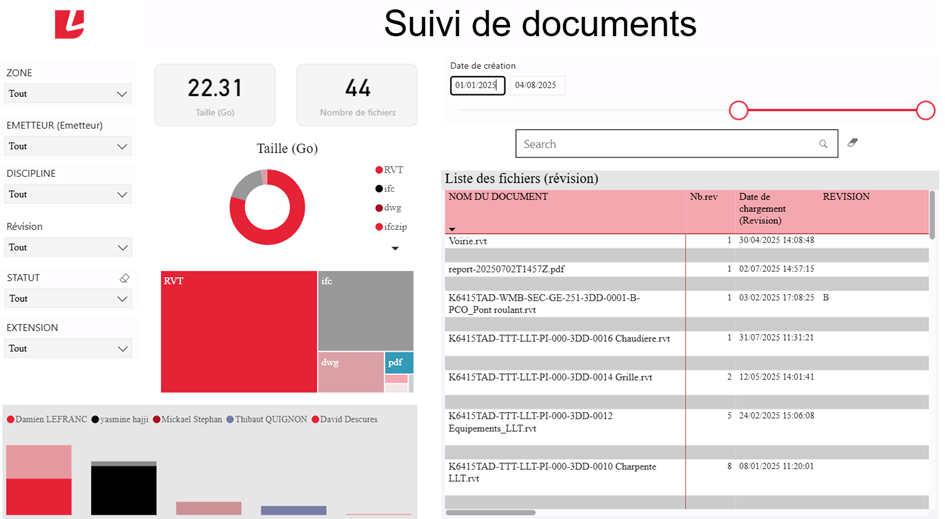

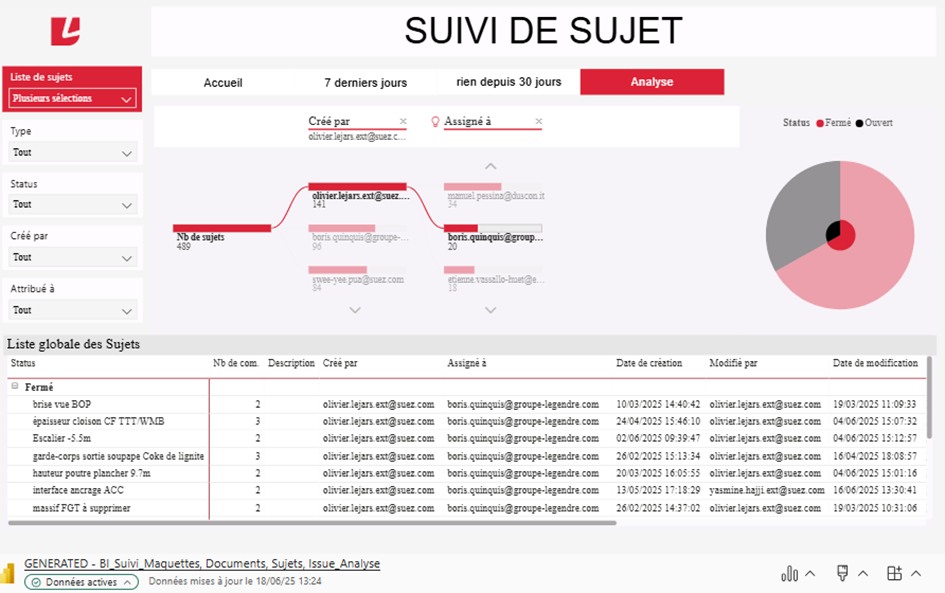

Legendre’s Digital Construction department is working to create clear, user-friendly dashboards powered by Catenda’s API and developed in partnership with the startup SeveUp. These dashboards, accessible via a single URL, provide a global overview of the project, including monitoring of models, documents, and issues related to design management, 3D coordination or any other subject requiring follow-up. This initiative is not just about the Taden project; it’s a pilot for a company-wide data strategy. “We want to test these dashboards on this project before proposing it to other projects,” Damien explains. “The open BIM approach adopted 10 years ago helps us to exchange with all professions including data managers.”

The Team Behind the Transformation

Damien was also keen to highlight the expertise of his team and their direct contributions to the project’s success. He thanked Aurélie Becerra and Gaëlle Rolland from the 3D design team for maintaining a “high level of requirement” in the models that are exchanged. Their work ensures that the client receives a high-quality final product.

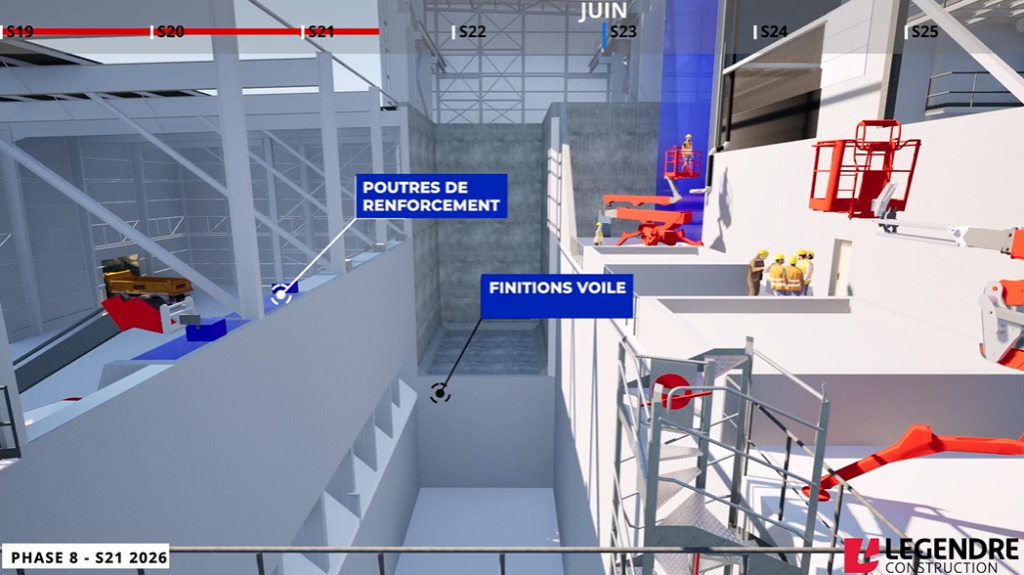

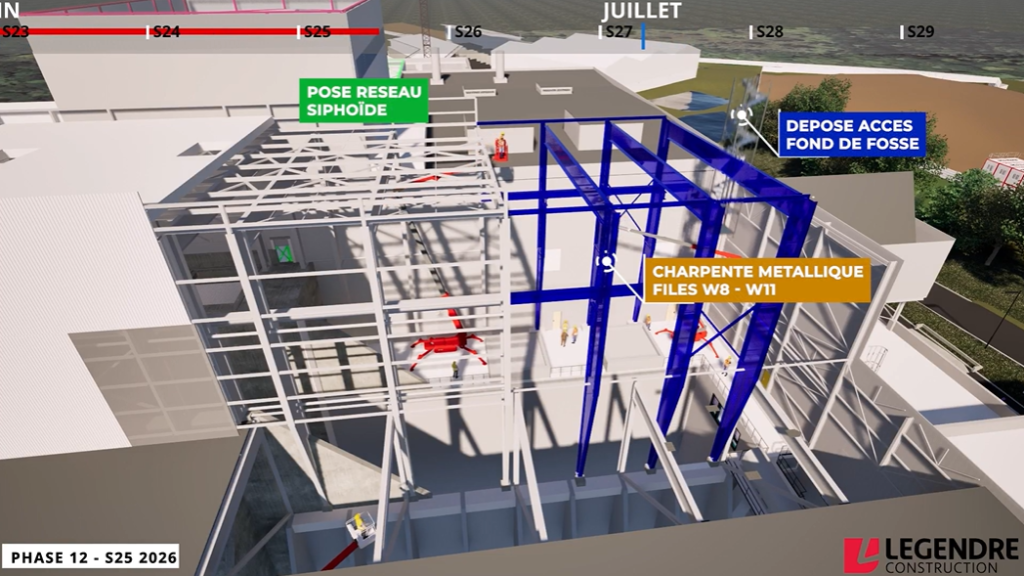

Additionally, the video phasing used to explain planning priorities was a key part of the project. This expertise was provided by Yann Le Loc’h from the Method department and Raphaël Daumer from the Digital Construction department.

The Future is Open

Looking ahead, Damien sees the future of digital construction for a general contractor like Legendre continuing down the path of open BIM, driven by two key challenges: data security (adopting standards like ISO 27001) and the rise of the open CDE.

He also shared his wishlist for new features, including better integration of point clouds, 4D capabilities to compare a digital model with real-time site progress, and the use of artificial intelligence to automate tasks like matching digital objects with their documentation. He is confident that these advancements are on the horizon.

In closing, he emphasizes that what they do at Legendre is an example that “BIM is no longer a subject for specialists”. By embracing open standards and prioritizing collaboration, Legendre is not just building structures; they are building a more efficient and transparent future for the entire AECO industry.

Image credit: Legendre Group