BIMLOGI Kajima Corporation

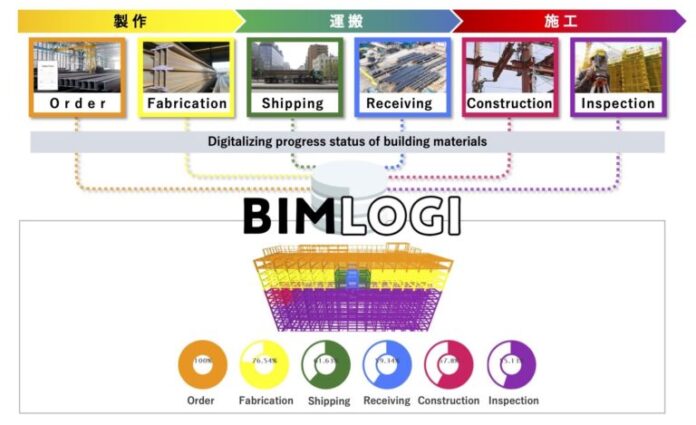

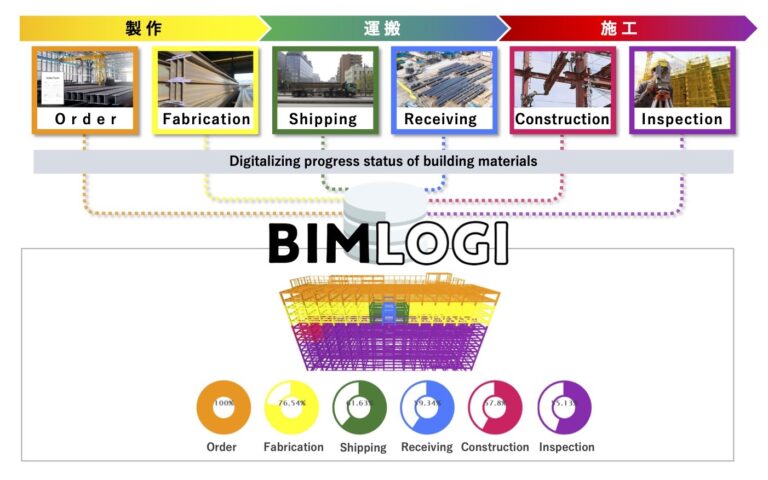

Overview and features of BIMLOGI – Catenda Boost for BIMLOGI

BIMLOGI, designed by Kajima Corporation, has been developed based on the Catenda Boost. Kajima strongly supports buildingSMART open standards, which makes Catenda Boost a perfect fit. Kajima and Catenda have worked together on many standards projects within buildingSMART International. Hence, it was natural to collaborate on this project as well. Catenda’s API allows Kajima to easily access Industry Foundation Class (IFC) data through a modern and flexible REST-based API, in addition to a powerful visualization engine. This combination has enabled Kajima to push new boundaries in logistics during the construction phase.

Kajima’s press release

BIMLOGI, designed by Kajima Corporation, has been developed to connect logistics data with BIM to optimise production, transportation and delivery of building materials and building products for any construction project. Using this brand new solution reduces production time and produces a documented digital twin at handover.

Kajima Corporation

Kajima Corporation reduced construction time using BIMLOGI for roughly 3,000 steel frameworks, 2,000 curtain wall works, 900 fittings works, and 60,000 electrical, air conditioning, and sanitary equipment works on a large-scale building site in Tokyo.

Kajima used site management technologies and environmental data such as CO2 emissions. The company included a tool for calculating CO2 emissions, in order to actively contribute to a decarbonized society by using this system to calculate CO2 emissions.

BIMLOGI Development

Background

Traditionally, controlling the production and construction progress of all the components that make up a building required the manager to visit the site and verify the development of each component at the factory, making comments and marks on the paper designs based on the information acquired. As a result, it was impossible to convey the latest development information between the parties involved smoothly and in a timely fashion, resulting in costly rework and slow performance, due to poor communication.

One of the core principles in Kajima is to make all processes digital in the Kajima Smart Production project. The idea is to encourage the digitization of all construction production processes based on Building Information Modeling (BIM). The system enables digital management of the production of factory-made materials and the construction progress through the model itself.

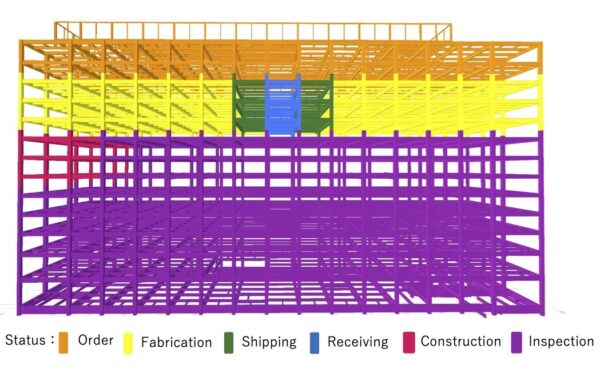

The BIMLOGI system combines each building product’s unique identity with the virtual objects in the BIM to manage the timing and outcome of each component from production, shipping, and transportation to site arrival, construction, and inspection. To keep track of the data, QR codes, with identifying information for each component, are used. The progress of each component is automatically recorded in the cloud-based system by scanning the QR codes on each building product during manufacturing using a smartphone at each phase of the building product lifecycle. Steel frames, external materials, interior materials, fittings, and sanitary, air conditioning, and electrical equipment are among the materials covered.

BIMLOGI – QR Code

Example of progress display

In addition, during the inspection phase, after the building products have been installed, punch lists can be defined for each component. The inspection can also be performed using drawings and recorded in the form of photographs. Since the results of the inspection are automatically recorded, it is easy to extract any parts that were not inspected.

Example of progress in BIMLOGI

Example of the inspection record screen

Screenshot BIMLOGI

BIMLOGI was first introduced at a primary construction site in Tokyo in April 2020. Kajima was able to share the manufacturing status of each component and the construction progress in real time among the various parties involved. Site management was more streamlined, including the virtual elimination of rework and waste in the construction work involved.

Future development

Kajima aims to further streamline site management by linking BIMLOGI to different site management tools already developed and by collecting and analyzing various construction data at the site.

In the future, when the amount of CO2 emitted during the manufacturing and transportation of each material becomes clear, the amount of CO2 emitted for each site will be known in a timely manner by integrating the progress data from this system. Given the need to understand and reduce CO2 emissions throughout the construction supply chain, stakeholders will use this system to promote initiatives to reduce CO2 emissions, such as more efficient transportation planning. This will make a positive contribution to the transition to a low-carbon society, which is one of the group’s priorities.

Kajima Corporation