What is BIM terminology?

BIM (Building Information Modeling) terminology refers to an array of terms and acronyms associated with the BIM process. These terms are important for understanding the different aspects of BIM, including its methodologies, technologies, and processes. They range from broad concepts such as BIM Levels and BIM Dimensions, to more specific terms like BEP (BIM Execution Plan) and EIR (Employer’s Information Requirements).

Understanding BIM terminology is crucial for professionals engaged in the planning, design, construction, and management of buildings. It aids in effective communication and collaboration among teams, enabling them to work efficiently across various stages of a project.

The following sections will delve deeper into 20 essential BIM terms, empowering you to navigate the world of BIM with confidence.

Navigating the BIM and construction Landscape: A Glossary of Key Terms

1. BIM – Building Information Modeling

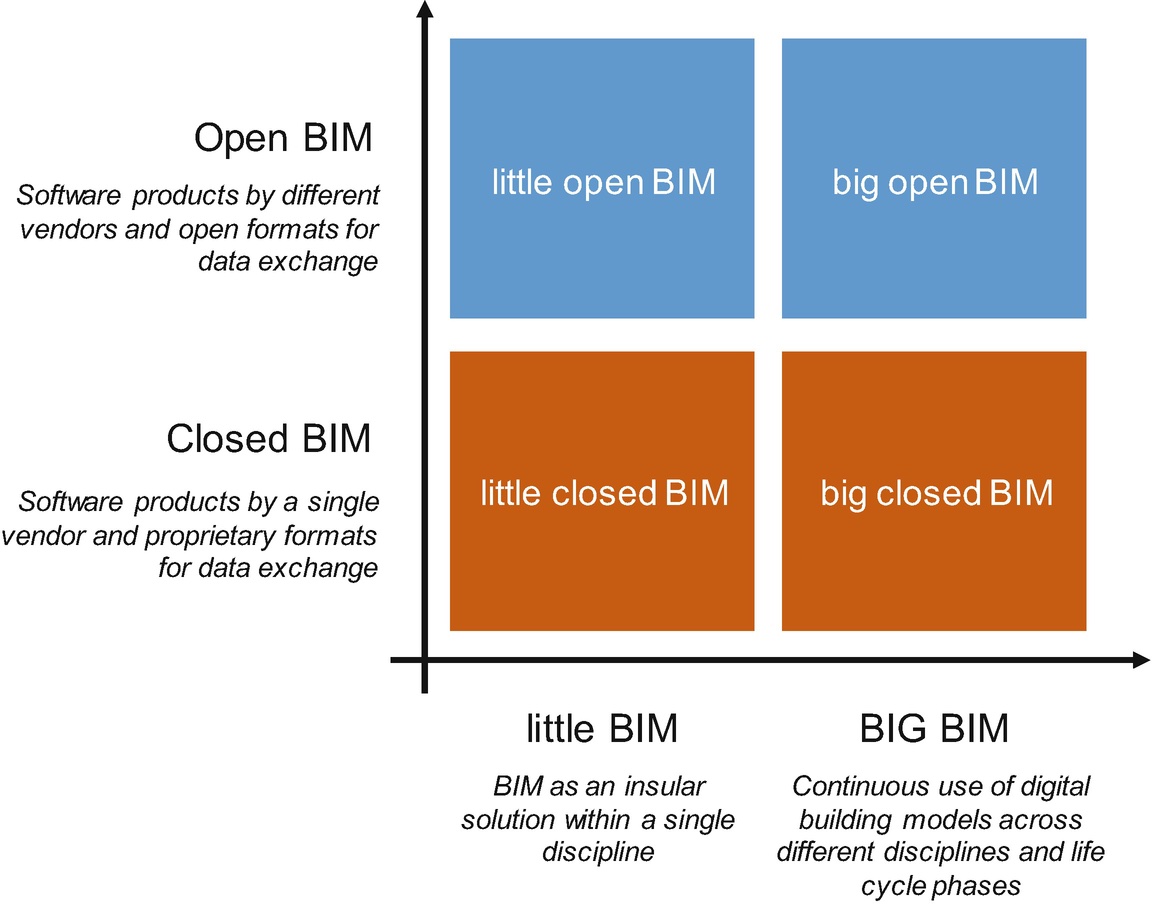

BIM stands for Building Information Modeling. Working methodologies and a 3D parametric digital model that contains intelligent and organized data are the core components of BIM. From design to demolition, BIM is the sharing of accurate information throughout the life of a building or infrastructure. The model is a computerized depiction of a building’s or infrastructure’s physical and functional qualities. BIM is often used as a reference to the actual model (or models), as well. However, the primary definition is focused on the process.

BIM is sometimes thought of as software or technology. That is not accurate. It is more accurately processes or workflows that are followed throughout the design, construction, and use of a structure. BIM, is an inclusive environment facilitating the contributions of the entire project team.

Learn more about BIM here.

2. BEP – BIM Execution Plan

The BIM Execution Plan (BEP) is a crucial document for a project’s effective BIM implementation. BEP includes the organization and graphical representation methods for the operation, the processes, models, and uses, according to the project’s specificities (i.e., rehabilitation, new, allotment, etc.). The BIM Execution Plan also establishes the responsibilities and accountability of team members, and the technologies that will be utilized on the project. In short, it describes the expectations for BIM use according to the project’s specifications

Learn more about BEP here.

Learn more about the benefits of BEP here.

3. CDE – Common Data Environment

A CDE collects all of the project’s shared data and makes it available to all of the participants. The formation of a CDE is a requirement for implementing BIM on a project.

Learn more about CDE here.

4. IFC – Industry Foundation Classes

IFC is an open BIM data interchange standard. It can be compared to a BIM PDF. IFC files are a frozen representation of the original material, similar to PDFs. They can be viewed, measured, and used for cost estimation or simulation, butt should not be altered. Because IFC is an open standard, it is constantly evolving.

Learn more about IFC here.

Discover a project case study explores the use of IFC files in overcoming real-world challenges.

5. BCF – BIM Collaboration Format

BCF is an open format, introduced by BuildingSMART, allowing concerns to be communicated between different BIM applications without submitting the entire model each time. The format makes it possible to keep track of issues. It also does not require the user to have licenses of all the software applications (i.e., the Designer can use the BCF that is created in a different software, simply by importing it into the BIM authoring technology).

Project members can collaborate even if they are using different BIMs because it is an open format. They can talk about concerns in a BIM by identifying locations in the models and communicating those places. The structure improves project member collaboration, lowers risks such as missing information, and speeds up the process.

Learn more about BCF here.

6. LOD – Level of Development

The stages of development are described by the Level of Development (LOD) in BIM. It’s a set of guidelines for AEC professionals to efficiently document, communicate, and specify BIM material. LOD is a standard that outlines how a building model’s 3D geometry can be developed to various levels of refinement and is used to assess the level of service required. It indicates how much various team members can rely on information regarding a specific component.

- LOD 100 – Conceptual / Pre-Design

- LOD 200 – Schematic Design

- LOD 300 – Design Development

- LOD 350 – Construction Documentation

- LOD 400 – Fabrication & assembly

- LOD 500 – Operational/As-built Models

Learn more about LOD here.

7. EIR – Employer’s Information Requirements

EIR (Employer’s Information Requirements) is a crucial document in the BIM process, as defined by PAS1192- 2 as a “pre-tender document setting out the information to be delivered, as well as the standards and processes to be adopted by the supplier as part of the project delivery process.” As a result, it’s a good place for clients to start while working on BIM projects. The Employer’s Information Requirements document gives detailed guidelines on how to complete a construction project.

Learn more about EIR here.

8. BIM Levels

- Level 0 – Building Information Modeling at this level simply comprises 2D CAD drawings (Computer-Aided Design). Only electronic printouts and paper are used to share files, papers, drawings, and other materials. Collaboration does not exist;

- Level 1 – It’s not only about 2D drawings here; 3-dimensional views are also considered. Teams share information using a Common Data Environment (CDE) in level 1 BIM. As a result, they can readily collaborate on initiatives;

- Level 2 – Everyone utilizes their own 3D CAD models, but they aren’t necessarily working on the same one. Collaboration happens between disciplines when a common file format, such as IFC (Industry Foundation Class), is used;

- Level 3 – BIM Level 3 is a fully integrated level in which all disciplines collaborate.

Learn more about BIM levels here.

9. BOS – Building Operating System

Also called middleware, a Building Operating System (BOS) establishes a bridge between the building equipment and external applications. The objective of BOS is to hide the building’s complexity while allowing easy access to data from the equipment. The BOS arranges and synchronizes the data from the field equipment, which is processed and translated into the correct format to fit smart building application requirements.

10. BIM Dimensions (2D, 3D, 4D, 5D, 6D, 7D)

The Building Information Modeling dimensions are the following:

- 2D – 2-dimension is made up of an X and Y-axis. Typically, these models are created by hand through the use of manual procedures or the use of computer-aided design (CAD) drawings;

- 3D – 3-dimensional modeling is a computer graphics approach for creating 3D representations (x, y, and z). That includes manipulating polygons, faces, and edges to create 3D objects and surfaces;

- 4D – 4-dimensional modeling integrates schedule data with an information model, adding the dimension of time to the project;

- 5D – 5D BIM is about cost estimation and budget analysis. 5D BIM assists in precisely forecasting budgetary requirements and variations in material, scope, equipment, and workforce;

- 6D – 6D BIM is related to sustainability, helping analyze a building’s energy consumption and the generation of energy estimates during the early stages of design;

- 7D – The 7th dimension in BIM helps to manage operations and facilities. All information about the facility management process is stocked in one place (associated with the model(s)). It helps enhance the quality of service delivery throughout a project’s lifecycle.

11. VDC – Virtual Design and Construction

VDC stands for Virtual Design and Construction. VDC is the use of an interdisciplinary performance model for a design project, including products, work processes, and design and operations team organizations to support business goals (Khanzode et al. 2006; Kunz & Fischer 2012). It has been created by Stanford University’s Center for Integrated Facility Engineering (CIFE).

Learn more about the definition of VDC here.

12. ICE – Integrated Concurrent Engineering

ICE stands for Integrated Concurrent Engineering meetings. The purpose of these meetings is to develop, display and describe the product as well as the organization, the 4D models, the processes and POP (Kunz). Therefore, it means that ICE meetings are interdisciplinary. They include the latest visualization techniques and enable simultaneous design work. Instead of exchanging email between disciplines, project members can introduce changes and approve them in a much more targeted way.

13. PPM – Project Production Management

PPM stands for Project Production Management. It strives to optimize cost, time, and scope through process design, capacity, inventory, and variability levers (www.projectproduction.org). PPM is an operations science applied to projects through the lens of a temporary production system. It’s science. Structuring and monitoring project work is an important element of PPM. Additionally, PPM determines the methodology for creating and using BIM, and the ICE meetings.

Learn more about VDC, ICE meetings and PPM here.

14. LEAN

Lean Manufacturing is based on the search for the most efficient production system and focuses on identifying and eliminating everything that does not add value to the final product. For this purpose, it establishes five assumptions:

- Set value concepts;

- Define the most efficient process for manufacturing a product;

- Eliminate fluctuations in the production process by establishing a continuous workflow;

- Use of a pull system;

- Continuous improvement.

Read more about Lean Management here.

15. ISO 19650

ISO 19650 certification is an international standard based on the old PAS 1192 (British Standard). PAS 1192 Publicly Available Specifications defines guidelines, practice standards, and norms developed to meet the needs of the construction industry.

ISO 19650 is a set of BIM (Building Information Modeling) standards, from concepts and principles to safety information about buildings and civil engineering. Certification includes different documents that define the collaboration process and describe the task.

- ISO 19650 – 1: Concepts

- ISO 19650 – 2: Delivery phase

- ISO 19650 – 3: Operational phase

- ISO 19650 – 4: Information exchange

- ISO 19650 – 5: Security

Read more about ISO 19650 here.

16. Clash detection

Clash detection is a technique used in BIM (Building Information Modeling). It is the automatic and computerized identification of conflicts or clashes. The technique speeds up projects by detecting conflicts between different models during the design process. It can be run on many 3D models.

Clash detection in BIM allows architects and contractors to avoid the effects of multi-level design revisions that can lead to cost overruns and project delays.

BIM Clash detection helps determine if building elements interfere with each other, where and how. Elements can be walls, systems, or any geometric object. It also helps to:

- Check the stability of the structure.

- Avoid schedule conflicts.

- And much more.

There are 3 types of clashes:

- Soft or ‘clearance’: object’s geometric tolerances, and allowable proximity

- Hard: two or more components occupy the same space, or geometric location

- Workflow or 4D clash: building information is incorrect or contradictory.

Read more about clash detection here.

17. BIM protocol

The Building Information Modeling (BIM) protocol contains provisions that support the creation of “data drop” deliverables during the defined project phases by creating requirements for suppliers to provide specified BIM at a defined level of detail.

The BIM protocol documents are typically provided as a professional consultant booking document and as an appendix to the contractor’s main contract, and the logs should be downgraded to the contractor’s supply chain.

18. AIR – Asset Information Requirements

AIR stands for Asset Information Requirements. They are part of the BIM process. AIR is defined by the ISO-19650 norm as “’information requirements in relation to the operation of an asset’; an information requirement is defined as ‘specification for what, when, how and for whom information is to be produced'” (source). AIR defines the graphical and non-graphical data, information and documentation needed for the lifetime operation and management of a built asset.

19. BuildingSMART Data Dictionary (bSDD)

BuildingsSMART International created bSDD (buildingSMART Data Dictionary).

The bSDD is an online service where users can find “classifications, standards, dictionaries and their properties, legal values, units, and translations”. It also contains specific standards regarding project, country, and company.

It is mainly used by BIM actors. The BIM modelers use bSDD to enrich their model. The BIM Manager uses bSDD to validate BIM data. Regarding other users, they use bSDD “to check compliance, automatically find manufacturer’s products, extend IFC (Industry Foundation Classes), create Information Delivery Specifications (IDS) and much more.” (www.buildingsmart.org).

20. Digital Twin

A digital twin is a virtual model that aims to accurately reflect a physical object or process. The objects are equipped with sensors which are related to important functional areas. The sensors generate data such as temperature, weather conditions, energy consumption etc. The data is fed into the processing system and applied to the digital copy.

When informed of this data, project members can use the virtual model to run simulations, investigate performance issues, and generate potential improvements. All of these elements are intended to generate valuable information and can be applied to the original physical object.

When a change occurs, it is implemented using engineering change orders (ECO). It will result in a new version of the item’s digital thread, and therefore the digital twin.

Read a full story about Digital Twin here.

Eva Stepak-Heritier, Marketing Director at Catenda.